BTP & BTS Electronics Manufacturing Services for Aerospace & Space

Azista delivers vertically integrated Electronics Design & Manufacturing Solutions, providing full lifecycle support: Design → Prototyping → Manufacturing → Lifecycle Management. We offer turnkey solutions for both Built to Print (BTP) and Built to Spec (BTS) projects, with flexibility tailored to customer requirements.

Fabrication & Assembly Services

Hi-Rel Fabrication for Mission-Critical Applications

- Specialization in Hi-Rel qualified processes including space-grade components.

RF & Microwave Payload Subsystems

- Components: 1GBPS X-Band Payload Transmitters, Low Noise Amplifiers, Frequency Converters, Receivers.

- Waveguide Passive Components: Filters, Couplers, etc.

- SDRs: VHF/UHF/L/S/C/X/Ka/Ku Band.

Advanced Hi-Rel Fabrication & Assembly

- Wire Bonding: MMIC, MIC, CMOS.

- Precision Die Bonding: Face Up & Flip Chip (Face Down).

- Automated Surface Mount Technologies (SMT)

- Robotic Selective Soldering: Through-hole (PTH) components.

- Multi-Chip Packaging: MCM, MCP.

- Micro-Optical Package Assembly

Testing & Infrastructure

Space-Grade Testing Facilities

- EMI/EMC testing: Anechoic Chamber (NABL accreditation in process).

- Thermal Vacuum Testing.

- Environmental Stress Screening (ESS).

- High-capacity Sine & Random Vibration & Mechanical Shock Testing (up to 6 ton).

Infrastructure Highlights

- Class-10000 Clean Rooms for MMIC/MIC/PFF assemblies.

- ESD-safe electronic assembly areas with automated SMT lines.

- 2.5D X-Ray system for BGA & fine-pitch inspections.

Quality & Compliance

- Certifications: ISO 9001:2015, AS 9100D:2016, ISO 45001:2018, CMMI Level 5.

- Standards Compliance: CIPC J-STD-001, IPC-A-610.

For the complete list of qualified processes, full testing capabilities, and standards, download the brochure.

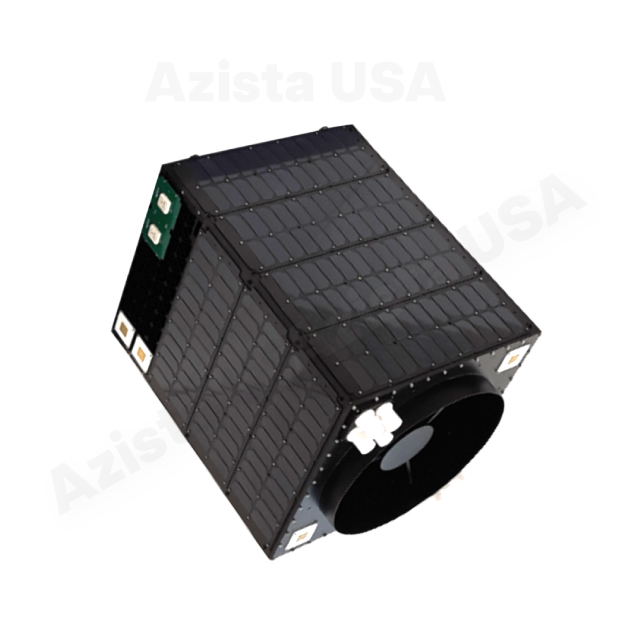

More Products from Satellites

Satellite Buses

AFR Bus

It delivers high-quality, on-demand satellite imagery for diverse civilian and defense applications.